| View previous topic :: View next topic |

| Author |

Message |

lmabadie

Joined: 06 Jul 2012

Posts: 13

|

Posted: Mon May 11, 2020 1:40 pm Post subject: Gulftech boom Posted: Mon May 11, 2020 1:40 pm Post subject: Gulftech boom |

|

|

I have an old Gulftech Pro Race carbon boom. It looks in good shape as far as all the main carbon parts, but the plastic head is broken. It seems this head is glued to the carbon arms. Any ideas on how to remove/repair? I need to replace the head but not sure where to start and where to get one that would fit and try to get it as original or if I need to try a completely different approach. Can somebody provide any lead on how to do this? I am quite handy and have done some repairs before, but never a carbon boom. [img][/img]

| Description: |

|

| Filesize: |

199.09 KB |

| Viewed: |

17430 Time(s) |

|

|

|

| Back to top |

|

|

mac

Joined: 07 Mar 1999

Posts: 17747

Location: Berkeley, California

|

Posted: Mon May 11, 2020 1:52 pm Post subject: Posted: Mon May 11, 2020 1:52 pm Post subject: |

|

|

| It depends on the age of the boom. I had multiple Gulftech's, and replaced the heads. But in the older design, the boom head had an aluminum male part that inserted into the arms, and that had to be removed--by dissolving the part with HCL and re-gluing the arms onto the head. Newer models were solid, so a new boom head could be clamped on the underlying carbon. Your picture looks like the old style, so it my not be worthwhile to try to dissolve the aluminum.

|

|

| Back to top |

|

|

swchandler

Joined: 08 Nov 1993

Posts: 10588

|

Posted: Mon May 11, 2020 4:56 pm Post subject: Posted: Mon May 11, 2020 4:56 pm Post subject: |

|

|

I have quite a few old Gulftech booms originally made in Corpus Christi, Texas. I even have one where the folks at Gulftech tried to repair it. It was a pretty useless attempt, especially with the funky plastic front end assembly they used.

The real problem is replicating the exact bend of the original front end, which was also used on Neil Pryde booms back then. I should point out that they also used the same front end on later Gulftech Glory carbon booms made in China in the early 2000s.

Given the fact that you can characterize the bend with your present boom, it would be possible to fabricate a special shaped carbon connecting component where you can bond the arms back on. Not as good as monocoque booms today, but potentially as good as later HPL booms, which are quite stiff and durable.

As far as the front end connector configuration, I would suggest going with the MauiSails carbon front end. If you're more inclined to the Streamlined design, you can plan for that in your design, but I'm thinking that the configuration (tube diameter and mounting area) might be the same between them.

If you pull the job off, I would be interested in seeing what you did.

|

|

| Back to top |

|

|

lmabadie

Joined: 06 Jul 2012

Posts: 13

|

Posted: Wed May 13, 2020 1:44 pm Post subject: Posted: Wed May 13, 2020 1:44 pm Post subject: |

|

|

Thank you guys for the input. It gave me enough for an idea that may work. PLease give me any other thought / suggestion.

What if I completely wipe out the clamping part of the broken front end and leave the rest that connects the carbon arms , leaving that untouched. Basically I would have a "monocoque" boom, made of carbon with a plastic/aluminum end that should keep the same structural integrity as the original. Then I would modify it as needed to be able to fit one of the heads that you mention that go over the front of the boom. The front of my boom would not be straight or the required diameter and I would need to supplement with carbon fiber or fiberglass to make it fit better. But that would have no structural impact even if I do a poor job.... I think I will try this, now I need to get a discarded head that I can fit or find a cheap new one.

|

|

| Back to top |

|

|

mac

Joined: 07 Mar 1999

Posts: 17747

Location: Berkeley, California

|

Posted: Wed May 13, 2020 1:49 pm Post subject: Posted: Wed May 13, 2020 1:49 pm Post subject: |

|

|

| If the connection between the two boom arms is intact, then shaving the old clamp off and installing a new clamp without disturbing the connection could work.

|

|

| Back to top |

|

|

swchandler

Joined: 08 Nov 1993

Posts: 10588

|

Posted: Wed May 13, 2020 5:12 pm Post subject: Posted: Wed May 13, 2020 5:12 pm Post subject: |

|

|

| Imabadie, I'm afraid it won't work. I should point out that what you have isn't a monocoque boom. The front end is bonded on. The inside of the bonded front end is a plastic encased aluminum tubular structure that is subject to corrosion. Even if you were to grind away most of the old front end, the shape that you're left with is too curved to accept either the MS or Streamlined aftermarket front ends. Best to fabricate a new carbon connection that joins the two boom arms. However, as I suggested earlier the tough part is designing the carbon connection component and putting it all together while maintaining the original bend curve.

|

|

| Back to top |

|

|

lmabadie

Joined: 06 Jul 2012

Posts: 13

|

Posted: Thu May 14, 2020 10:54 am Post subject: Posted: Thu May 14, 2020 10:54 am Post subject: |

|

|

| THanks again. I understand the curvature option issue. I think I will go with plan A that is shaving the existing clamp. I think I can add two "rings" or bushings made with fiberglass around the curved portion where the clamp contacts it to make it straight enough (relative to each other) so that the clamp on head would attach properly, i do not think I need to straighten the whole thing. It that does not work, then I can go to Plan B which is to make a new connection part, but it seems that it would be worth to leave as much of the existing part (aluminum / plastic) underneath anyway without completely cutting it away. Some minor added weight but wild give me more confidence that the proper joints are made. Now the challenge is to get the clamp on head, at more than $100 new and not knowing for sure my repair will work I will try to get used, if you have any hint on that regard, I would appreciate it

|

|

| Back to top |

|

|

dhmark

Joined: 04 Sep 2007

Posts: 376

|

Posted: Fri May 15, 2020 7:28 am Post subject: Posted: Fri May 15, 2020 7:28 am Post subject: |

|

|

| Call up Chinook and see if they have any triple clamps. Maybe you are lucky and the angle matches.

|

|

| Back to top |

|

|

thombiz

Joined: 25 Jun 2007

Posts: 799

Location: Corpus Christi

|

Posted: Fri May 15, 2020 12:23 pm Post subject: Posted: Fri May 15, 2020 12:23 pm Post subject: |

|

|

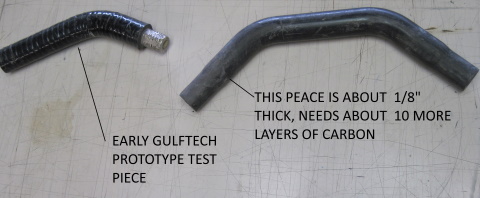

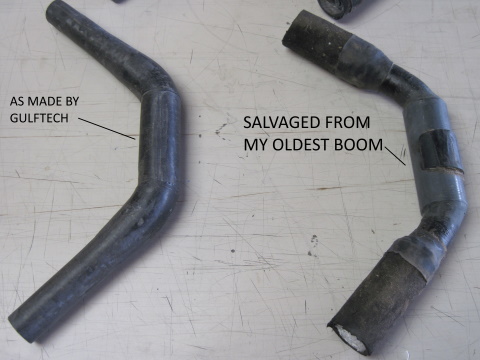

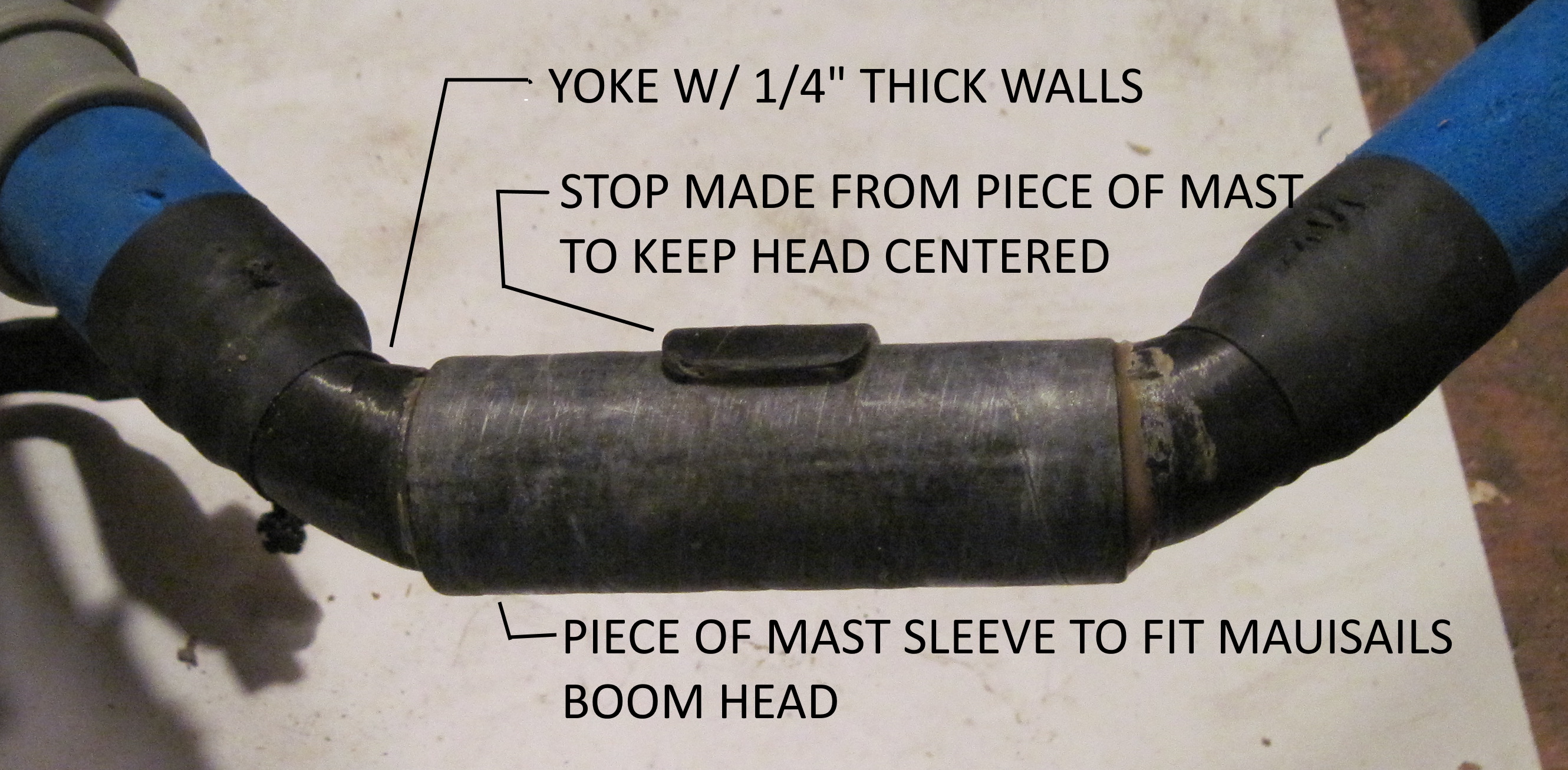

Imabadie, I have your answer and I think I have the exact thing you need to solve the problem. A little background...I'm the sail repair guy in Corpus and was friends with Don McCormick of Gulftech. When Don's shop closed another company called Stiffy Poles moved into the space. Some of the workers were former Gulftech employees and were friends. They used to let me come over and pick thru the leftovers from Gulftech. Picking thru the leftovers, I found some prototype carbon yokes Don had made to replace the aluminum "yoked" heads he had been using. I have used said yokes to retrofit my Gulftech boom heads as they went bad. Good news... I think I still have a few of those carbon yokes. The solution is cut away the plastic wrap on the oem aluminum yoke, then soak the yoke and the forward part of the arms in pool cleaning acid until the aluminum is eaten away. This will leave the remnants of resin and fiberglass (not carbon) that was used to bond the OEM yoke to the carbon arm pieces. You will need to use a sharpened point small flat blade screwdriver and a hammer to gently chip away at that fiberglass and filler and resin used to bond the OEM head to the arms to expose the carbon of the boom arm. With both arms cleaned you will need to create 2 styrofoam plugs to go into the front end of each arm. The purpose of these plugs is keep the epoxy resin from going down the arm when you glue in the carbon yoke. Basically they are just dams to control the location of the epoxy. Epoxy the yoke in using a high density filler in the resin, this will help hold the resin in place while it sets up and it will be strong as a structural adhesive for the carbon yoke. Mix to a consistency of barely runny peanut butter. If the diameter of the yoke where a MauiSails head would mount is not the diameter needed by the MauiSails head then you will need to build it up until it is the right diameter. I usually use pieces of broken masts to build up the yoke as needed. Then ad an additional piece to keep the MauiSails head from sliding back and forth across the yoke tube. I will get back to this post this afternoon once I locate a yoke and can get pics of what I am describing. I' ve had this solution in 3 booms for nearly 15 years with not a single problem. I just replace the MauiSails head as needed.

| Description: |

|

| Filesize: |

40.24 KB |

| Viewed: |

17070 Time(s) |

|

| Description: |

|

| Filesize: |

58.18 KB |

| Viewed: |

17070 Time(s) |

|

| Description: |

|

| Filesize: |

61.13 KB |

| Viewed: |

17070 Time(s) |

|

| Description: |

|

| Filesize: |

1.06 MB |

| Viewed: |

17072 Time(s) |

|

Last edited by thombiz on Fri May 15, 2020 4:54 pm; edited 1 time in total |

|

| Back to top |

|

|

dhmark

Joined: 04 Sep 2007

Posts: 376

|

Posted: Fri May 15, 2020 4:05 pm Post subject: Posted: Fri May 15, 2020 4:05 pm Post subject: |

|

|

| Thombiz is one of the gems of this form, astounding knowledge and advice. I think Mauisails or Streamlined boom heads very pricey and lack some features, but certainly perform well. Cheaper options with built-in RDM shims include Chinook, Aeron, or Duotone.

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You can attach files in this forum

You can download files in this forum

|

|

|